The Project Gutenberg EBook of Scientific American Supplement, No. 315, January 14, 1882, by Various This eBook is for the use of anyone anywhere at no cost and with almost no restrictions whatsoever. You may copy it, give it away or re-use it under the terms of the Project Gutenberg License included with this eBook or online at www.gutenberg.org Title: Scientific American Supplement, No. 315, January 14, 1882 Author: Various Release Date: May 8, 2006 [EBook #18345] Language: English Character set encoding: ISO-8859-1 *** START OF THIS PROJECT GUTENBERG EBOOK SCIENTIFIC AMERICAN *** Produced by Juliet Sutherland and the Online Distributed Proofreading Team at www.pgdp.net

In admiring the recent developments of electric science as evidenced by the number of important inventions which have during the past few years been given to the world, especially in those branches of applied science which deal more particularly with the generation of electricity and the production of the electric light, there is often too great a tendency to forget, or, at least, to pass over in comparative silence the claims which the great pioneer workers and discoverers undoubtedly have to a large share of the merit of this scientific development.

It is, of course, obviously impossible in anything approaching a retrospect of the science of magneto-electric induction or its application to illumination to pass slightly over the names of Oersted, of Ampère, of Davy, and of Faraday, but, in other respects, their work is too often lost sight of in the splendid modern developments of their discoveries. Again, there is another group of discoverer-inventors who occupy an intermediate position between the abstract discoverers above named and the inventors and adapters of still more recent times. To this group belong the names of Pixii and Saxton, Holmes and Nollet, Wilde, Varley, Siemens, Wheatstone, and Pacinotti, who was the first to discover a means of constructing a machine capable of giving a continuous current always in the same direction, and which has since proved itself to be the type of nearly all the direct current electric machines of the present day, and especially those such as the Gramme and Brush and De Meritens machines, in which the rotating armature is of annular form; and when it is considered what a large number of the well known electric generators are founded upon this discovery, it must be a matter of general gratification that the recent International Jury of the Paris Exhibition of Electricity awarded to Dr. Antonio Pacinotti one of their highest awards.

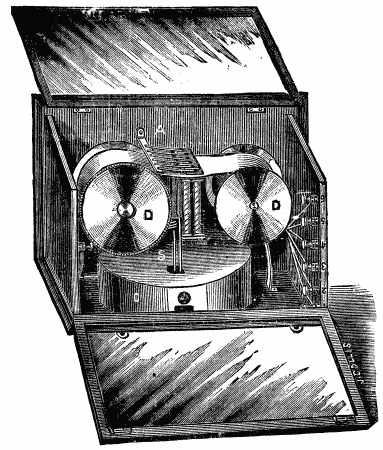

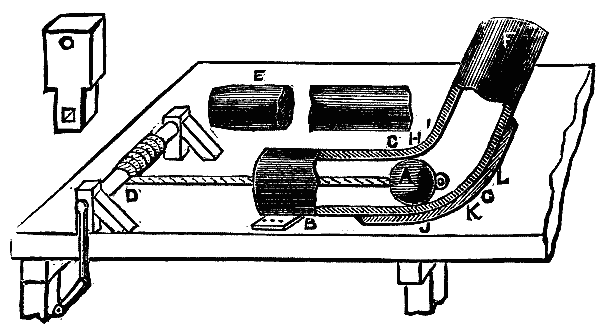

The original machine designed by Dr. Pacinotti in the year 1860, and which we illustrate on the present page, formed one of the most interesting exhibits in the Paris Exhibition, and conferred upon the Italian Section a very distinctive feature, and we cannot but think that while all were interested in examining it, there must have been many who could not help being impressed with the fact that it took something away from the originality of design in several of the machines exhibited in various parts of the building.

This very interesting machine was first illustrated and described by its inventor in the Nuovo Cimento in the year 1864, under the title "A Description of a Small Electro-Magnetic Machine," and to this description we are indebted for the information and diagrams contained in this notice, but the perspective view is taken from the instrument itself in the Paris Exhibition.

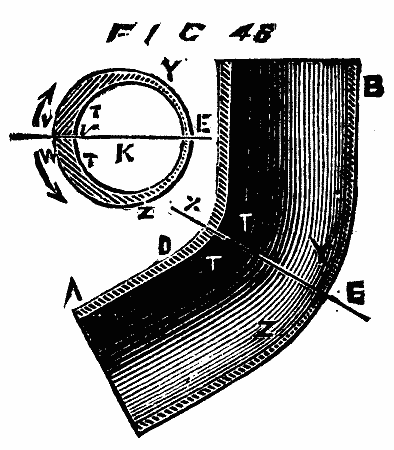

In this very interesting historical communication the author commences by describing a new form of electro-magnet, consisting of an iron ring around which is wound (as in the Gramme machine) a single helix of insulated copper wire completely covering the ring, and the two ends of the annular helix being soldered together, an annular magnet is produced, enveloped in an insulated helix forming a closed circuit, the convolutions of which are all in the same direction. If in such a system any two points of the coil situated at opposite ends of the same diameter of the ring be connected respectively with the two poles of a voltaic battery, the electric current having two courses open to it, will divide into two portions traversing the coil around each half of the ring from one point of contact to the other, and the direction of the current, in each portion will be such as to magnetize the iron core, so that its magnetic poles will be situated at the points where the current enters and leaves the helix, and a straight line joining these points may be looked upon as the magnetic axis of the system. From this construction it is clear that, by varying the position of the points of contact of the battery wires and the coil, the position of the magnetic axis will be changed accordingly, and can be made to take up any diametrical position with respect to the ring, of which the two halves (separated by the diameter joining the points of contact of the battery wires with the coil) may be regarded as made up of two semicircular horseshoe electro-magnets having their similar poles joined. To this form of instrument the name "Transversal electro magnet" (Eletro calamita transversale) was given by its inventor, to whom is undoubtedly due the merit of having been the first to construct an electro-magnet the position of whose poles could be varied at will by means of a circular commutator.

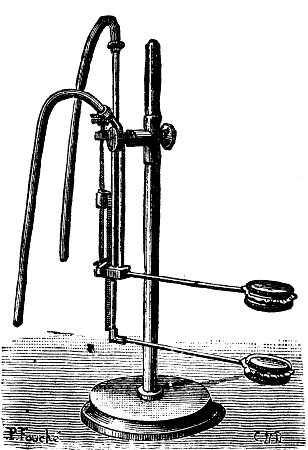

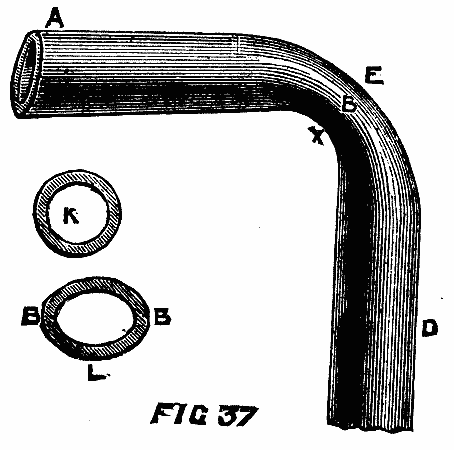

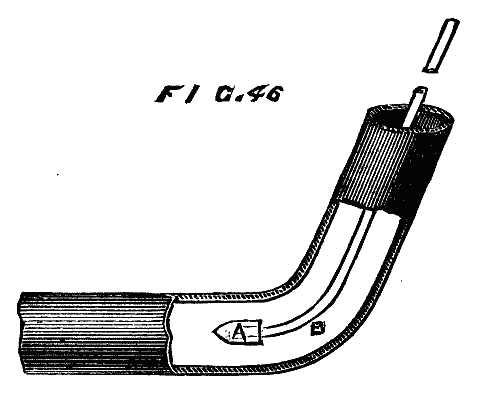

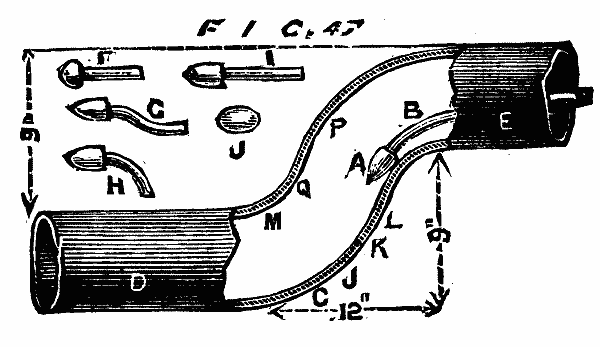

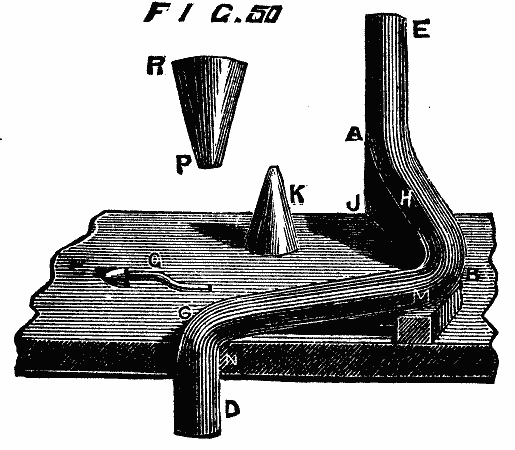

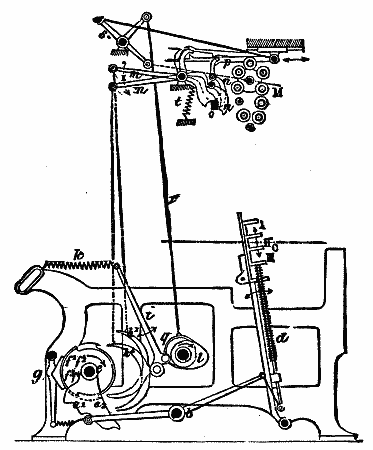

By applying the principle to an electro-magnetic engine, Dr. Pacinotti produced the machine which we illustrate on the present page. The armature consists of a turned ring of iron, having around its circumference sixteen teeth of equal size and at equal angular distance apart, as shown in Fig. 1, forming between them as many spaces or notches, which are filled up by coiling within them helices of insulated copper wire, r r r, in a similar manner to that adopted in winding the Brush armature, and between them are fixed as many wooden wedges, m m, by which the helices are firmly held in their place. All the coils are wound round the ring in the same direction, and the terminating end of each coil is connected to the commencing end of the next or succeeding helix, and the junctions so made are attached to conducting wires which are gathered together close to the vertical shaft on which the armature ring is fixed, passing through holes at equal distances apart in a wooden collar fixed to the same shaft, and being attached at their lower extremities to the metallic contact pieces of the commutator, c, shown at the lower part of Fig. 3, which is an elevation of the machine, while Fig. 4 is a plan of the same apparatus.

The commutator consists of a small boxwood cylinder, carrying around its cylindrical surface two rows of eight holes, one above the other, in which are fitted sixteen contact pieces of brass which slightly project above the surface of the wood, the positions of those in the upper circle alternating or "breaking joint" with those in the lower, and each contact piece is in metallic connection with its corresponding conducting wire, and, therefore, with the junction of two of the helices on the armature. Against the edge of the commutator are pressed by means of adjustable levers two small brass contact rollers, k k, which are respectively connected with the positive and negative poles of the voltaic battery (either through or independent of the coils of a fixed electro-magnet, to which we shall presently refer), and the magnetic axis of the ring will lie in the same plane as the line joining the points of contact of the battery and rotating helix, this axis remaining nearly fixed notwithstanding the rotation of the iron ring in which the magnetism is induced.

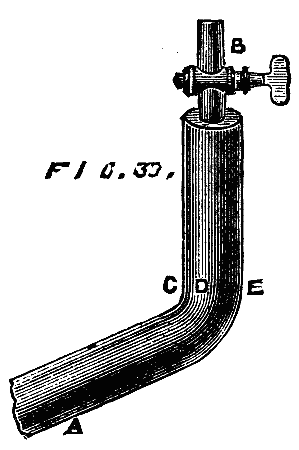

In the apparatus figured in Figs. 3 and 4, the armature rotates between the two vertical limbs, A B, of a fixed electro-magnet furnished with extended pole pieces, A A, B B (Fig. 4), each of which embraces about six of the armature coils. The fixed electro-magnet is constructed of two vertical iron cylindrical bars, A and B, united at their lower extremities by a horizontal iron bar, F F, the one being rigidly and permanently attached to it, while the other is fastened to it by a screw, G, passing through a slot so that the distance of the pole pieces from one another and from the armature ring is capable of adjustment.

The connections of the machine, which are shown in Fig. 3, are made as follows: The positive current, entering by the attachment screw, h, passes by a wire to the right hand commutator screw, l, to the right-hand roller, k, through the commutator to the ring, around which it traverses to the left-hand roller, k¹, and screw, l¹, to the magnet coil, A, and thence through the coil of the magnet, B, to the terminal screw, h, on the right hand of the figure. This method of coupling up is of very great historical interest, for it is the first instance on record of the magnet coils and armature of a machine being included in one circuit, giving to it the principle of construction of a dynamo-electric machine, and antedating in publication, by two years, the interesting machines of Siemens, Wheatstone, and Varley, and preceding them in construction by a still longer period.

With this apparatus Dr. Pacinotti made the following interesting experiments with the object of determining the amount of mechanical work produced by the machine (when worked as an electro-magnetic engine), and the corresponding consumption of the elements of the battery: Attached to the spindle of the machine was a small pulley, Q Q (Fig. 3), for the purpose of driving, by means of a cord, another pulley on a horizontal spindle carrying a drum on which was wound a cord carrying a weight, and on the same spindle was also a brake and brake-wheel, the lever of which was loaded so as just to prevent the weight setting into motion the whole system, consisting of the two machines, when no current was flowing. In this condition, when the machine was set in motion by connecting the battery, the mechanical work expended in overcoming the friction of the brake was equal to that required to raise the weight; and, in order to obtain the total work done, all that was necessary was to multiply the weight lifted by the distance through which it was raised. The consumption of the battery was estimated at the same time by interposing in the circuit a sulphate of copper voltameter, of which the copper plate was weighed before and after the experiment. The following are some of the results obtained by Dr. Pacinotti in experimenting after the manner just described. With the current from a battery of four small Bunsen elements, the machine raised a weight of 3.2812 kilos to a height of 8.66 m. (allowing for friction), so that the mechanical work was represented by 28.45 m. During the experiment the positive plate of the voltameter lost in weight 0.224 gramme, the negative gaining 0.235 gramme, giving an average of chemical work performed in the voltameter of 0.229 gramme, and multiplying this figure by the ratio between the equivalent of zinc to that of copper, and by the number of the elements of the battery, the weight of zinc consumed in the battery was computed at 0.951 gramme, so that to produce one kilogrammeter of mechanical work 33 milligrammes of zinc would be consumed in the battery. In another experiment, made with five elements, the consumption of zinc was found to be 36 milligrammes for every kilogrammeter of mechanical work performed. In recording these experiments, Dr. Pacinotti points out that although these results do not show any special advantage in his machine over those of other construction, still they are very encouraging, when it is considered that the apparatus with which the experiments were made were full of defects of workmanship, the commutator, being eccentric to the axis, causing the contacts between it and the rollers to be very imperfect and unequal.

In his communication to the Nuovo Cimento, Dr. Pacinotti states that the reasons which induced him to construct the apparatus on the principle which we have just described, were: (1) That according to this system the electric current is continuously traversing the coils of the armature, and the machine is kept in motion not by a series of intermittent impulses succeeding one another with greater or less rapidity, but by a constantly acting force producing a more uniform effect. (2) The annular form of the revolving armature contributes (together with the preceding method of continuous magnetization) to give regularity to its motion and at the same time reduces the loss of motive power, through mechanical shocks and friction, to a minimum. (3) In the annular system no attempt is made suddenly to magnetize and demagnetize the iron core of the rotating armature, as such changes of magnetization would be retarded by the setting up of extra currents, and also by the permanent residual magnetism which cannot be entirely eliminated from the iron; and with this annular construction such charges are not required, all that is necessary being that each portion of the iron of the ring should pass, in its rotation, through the various degrees of magnetization in succession, being subjected thereby to the influence of the electro-dynamic forces by which its motion is produced. (4) The polar extension pieces of the fixed electro-magnet, by embracing a sufficiently large number of the iron projecting pieces on the armature ring, continue to exercise an influence upon them almost up to the point at which their magnetization ceases when passing the neutral axis. (5) By the method of construction adopted, sparks, while being increased in number, are diminished in intensity, there being no powerful extra currents produced at the breaking of the circuit, and Dr. Pacinotti points out that when the machine is in rotation a continuous current is induced in the circuit which is opposed to that of the battery; and this leads to what, looked at by the light of the present state of electric science, is by far the most interesting part of Dr. Pacinotti's paper, published, as it was, more than seventeen years ago.

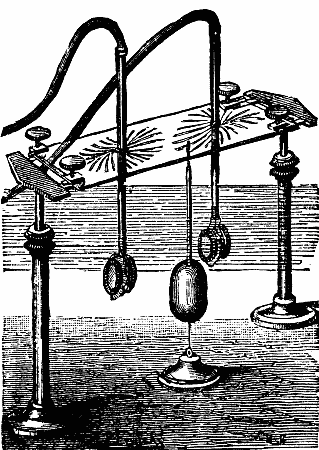

In the part to which we refer, Dr. Pacinotti states that it occurred to him that the value of the apparatus would be greatly increased if it could be altered from an electro-magnetic to a magneto-electric machine, so as to produce a continuous current. Thus, if the electro-magnet, A B (Figs. 3 and 4), be replaced by a permanent magnet, and the annular armature were made to revolve, the apparatus would become a magneto-electric generator, which would produce a continuous induced current always in the same direction, and in analyzing the action of such a machine Dr. Pacinotti observes that, as the position of the magnetic field is fixed, and the iron armature with its coils rotates within it, the action may be regarded as the same as if the iron ring were made up of two fixed semicircular horseshoe magnets with their similar poles joined, and the coils were loose upon it and were caused to rotate over it, and this mode of expressing the phenomenon was exactly what we adopted when describing the Gramme machine, without having at that time seen what Dr. Pacinotti had written fifteen years before.

In explanation of the physical phenomena involved in the induction of the electric currents in the armature when the machine is in action as a generator, Dr. Pacinotti makes the following remarks: Let us trace the action of one of the coils in the various positions that it can assume in one complete revolution; starting from the position marked N, Fig. 2, and moving toward S, an electric current will be developed in it in one direction while moving through the portion of the circle, N a, and after passing the point, a, and while passing through the arc, a S, the induced current will be in the opposite direction, which direction will be maintained until the point, b, is reached, after which the currents will be in the same direction as between N and a; and as all the coils are connected together, all the currents in a given direction will unite and give the combined current a direction indicated by the arrows in Fig. 2, and in order to collect it (so as to transmit it into the external circuit), the most eminent position for the collectors will be at points on the commutator at opposite ends of a diameter which is perpendicular to the magnetic axis of the magnetic field. With reference to Fig. 2, we imagine either that the two arrows to the right of the figure are incorrectly placed by the engraver, or that Dr. Pacinotti intended this diagram to express the direction of the current throughout the whole circuit, as if it started from a, and after traversing the external circuit entered again at b, thus completing the whole cycle made up of the external and internal circuits.

Dr. Pacinotti calls attention to the fact that the direction of the current generated by the machine is reversed by a reversal of the direction of rotation, as well as by a shifting of the position of the collectors from one side to the other of their neutral point, and concludes his most interesting communication by describing experiments made with it in order to convert it into a magneto-electric machine. "I brought," he says, "near to the coiled armature the opposite poles of two permanent magnets, and I also excited by the current from a battery the fixed electro-magnets (see Figs. 3 and 4), and by mechanical means I rotated the annular armature on its axis. By both methods I obtained an induced electric current, which was continuous and always in the same direction, and which, as was indicated by a galvanometer, proved to be of considerable intensity, although it had traversed the sulphate of copper voltameter which was included in the circuit."

Dr. Pacinotti goes on to show that there would be an obvious advantage in constructing electric generating machines upon this principle, for by such a system electric currents can be produced which are continuous and in one direction without the necessity of the inconvenient and more or less inefficient mechanical arrangements for commutating the currents and sorting them, so as to collect and combine those in one direction, separating them from those which are in the opposite; and he also points our the reversibility of the apparatus, showing that as an electro-magnetic engine it is capable of converting a current of electricity into mechanical motion capable of performing work, while as a magneto-electric machine it is made to transform mechanical energy into an electric current, which in other apparatus, forming part of its external circuit, is capable of performing electric, chemical, or mechanical work.

All these statements are matters of everyday familiarity at the present day, but it must be remembered that they are records of experiments made twenty years ago, and as such they entitle their author to a very distinguished place among the pioneers of electric science, and it is somewhat remarkable that they did not lead him straight to the discovery of the "action and reaction" principle of dynamo-electric magnetic induction to which he approached so closely, and it is also a curious fact that so suggestive and remarkable a paper should have been written and published as far back as 1864, and that it should not have produced sooner than it did a revolution in electric science.—Engineering.

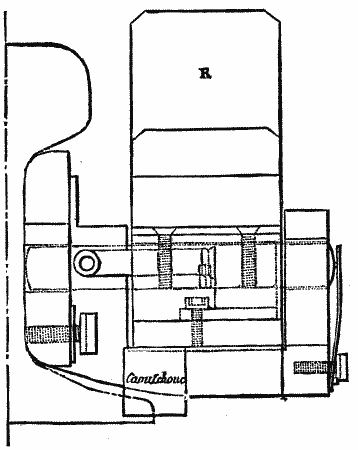

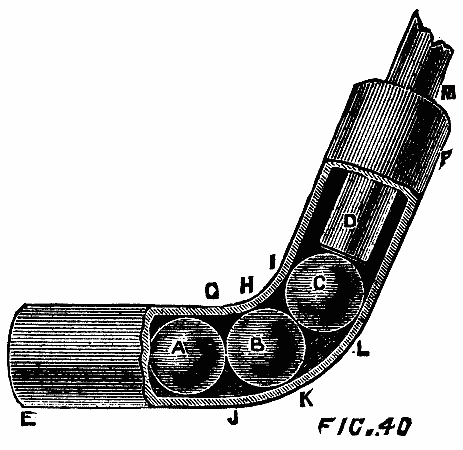

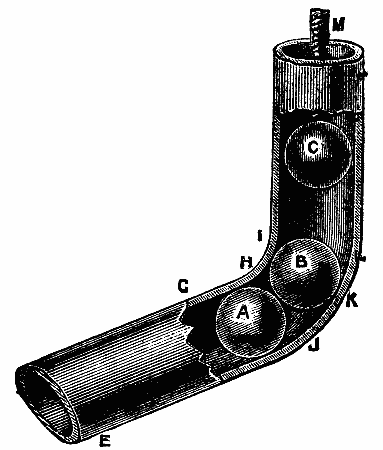

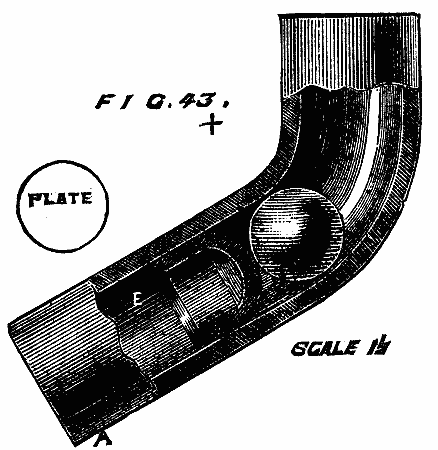

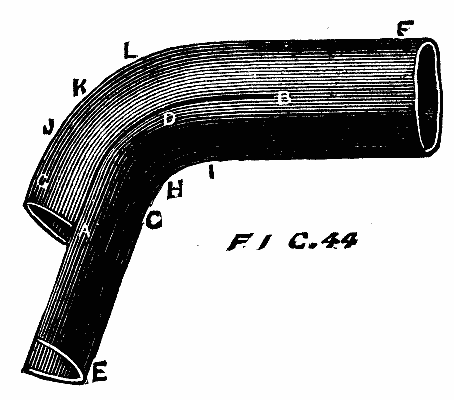

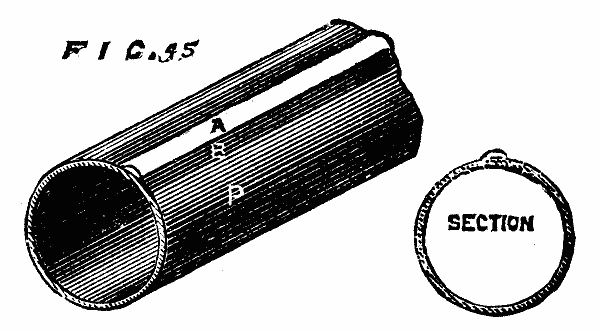

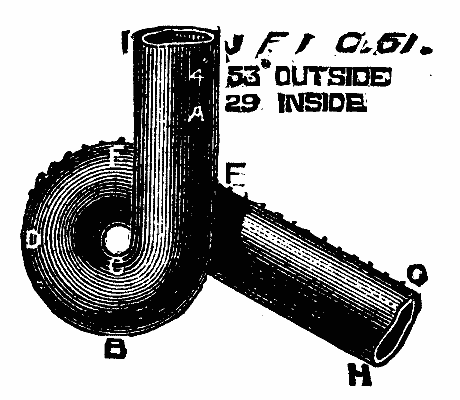

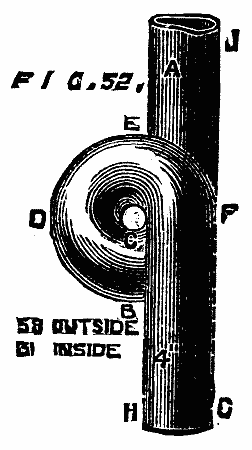

We lately published a short description of a very interesting apparatus which may be considered in some sense as a prototype of the Gramme machine, although it has very considerable, indeed radical differences, and which, moreover, was constructed for a different purpose, the Elias machine being, in fact, an electromotor, while the Gramme machine is, it is almost unnecessary to say, an electric generator. This apparent resemblance makes it, however, necessary to describe the Elias machine, and to explain the difference between it and the Gramme. Its very early date (1842), moreover, gives it an exceptional interest. The figures on the previous page convey an exact idea of the model that was exhibited at the Paris Electrical Exhibition, and which was contributed by the Ecole Polytechnique of Delft in the Dutch Section. This model is almost identical with that illustrated and described in a pamphlet accompanying the exhibit. The perspective illustrations show the machine very clearly, and the section explains the construction still further. The apparatus consists of an exterior ring made of iron, about 14 in. in diameter and 1.5 in wide. It is divided into six equal sections by six small blocks which project from the inner face of the ring, and which act as so many magnetic poles. On each of the sections between the blocks is rolled a coil, of one thickness only, of copper wire about 0.04 in. in diameter, inclosed in an insulating casing of gutta percha, giving to the conductor thus protected a total thickness of 0.20 in.; this wire is coiled, as shown in the illustration. It forms twenty-nine turns in each section, and the direction of winding changes at each passage in front of a pole piece. The ends of the wire coinciding with the horizontal diameter of the ring are stripped of the gutta percha, and are connected to copper wires which are twisted together and around two copper rods, which are placed vertically, their lower ends entering two small cavities made in the base of the apparatus. The circuit is thus continuous with two ends at opposite points of the same diameter. The ring is about 1.1 in. thick, and is fixed, as shown, to two wooden columns, B B, by two blocks of copper, a.

It will be seen from the mode of coiling the wire on this ring, that if a battery be connected by means of the copper rods, the current will create six consecutive poles on the various projecting blocks. The inner ring, E, is about 11 in. in outside diameter, and is also provided with a series of six projecting pieces which pass before those on the exterior ring with very little clearance. Between these projections the space between the inner face of the outer, and the outer face of the inner ring, is 0.40 in. The latter is movable, and is supported by three wooden arms, F, fixed to a boss, G, which is traversed by a spindle supported in bearings by the columns, A and C. A coil is rolled around the ring in exactly the same way as that on the outer ring, the wire being of the same size, and the insulation of the same thickness. The ends of the wire are also bared at points of the diameter opposite each other, and the coil connected in pairs so as to form a continuous circuit. At the two points of junction they are connected with a hexagonal commutator placed on the central spindle, one end corresponding to the sides 1, 3, and 5, and the other to the sides 2, 4, and 6. Two copper rods, J, fixed on the base to two plates of copper furnished with binding screws, are widened and flattened at their upper ends to rest against opposite parallel sides of the hexagon. It will be seen that if the battery is put in circuit by means of the binding screws, the current in the interior ring will determine six consecutive poles, the names of which will change as the commutator plates come into contact successively with the sides of the hexagon. Consequently, if at first the pole-pieces opposite each other are magnetized with the same polarity, a repulsion between them will be set up which will set the inner ring in motion, and the effect will be increased on account of the attraction of the next pole of the outer ring. At the moment when the pole piece thus attracted comes into the field of the pole of opposite polarity, the action of the commutator will change its magnetization, while that of the pole-piece on the fixed ring always remains the same; the same phenomenon of repulsion will be produced, and the inner ring will continue its movement in the same direction, and so on. To the attractive and repulsive action of the magnetic poles has to be added the reciprocal action of the coils around the two rings, the action of which is similar. From this brief explanation the differences between the Elias machine and the Gramme will be understood. The Dutch physicist did not contemplate the production of a current; he utilized two distinct sources of electricity to set the inner ring in motion, and did not imagine that it was possible, by suppressing one of the inducing currents and putting the ring in rapid rotation, to obtain a continuous current. Moreover, if ever this apparent resemblance had been real, the merit of the Gramme invention would not have been affected by it. It has happened very many times that inventors living in different countries, and strangers to one another, have been inspired with the same idea, and have followed it by similar methods, either simultaneously or at different periods, without the application having led to the same results. It does not suffice even for the seed to be the same; it must have fallen in good ground, and be cultivated with care; here it scarcely germinates, there it produces a vigorous plant and abundant fruit.—Engineering.

As a general thing, too much trust should not be placed in words. In the first place, it frequently happens that their sense is not well defined, or that they are not understood exactly in the same way by everybody, and this leads to sad misunderstandings. But even in case they are precise, and are received everywhere under a single acceptation, there still remains one danger, and that is that of passing from the word to the idea, and of being led to believe that, because there is a word, there is a real thing designated by this word.

Let us take, for example, the word electricity. If we understand by this term the common law which embraces a certain category of phenomena, it expresses a clear and useful idea; but as for its existence, it is not permitted to believe a priori that there is a distinct agent called electricity which is the efficient cause of the phenomena. We ought never, says the old rule of philosophy, to admit entities without an absolute necessity. The march of science has always consisted in gradually eliminating these provisory conceptions and in reducing the number of causes. This fact is visible without going back to the ages of ignorance, when every new phenomenon brought with it the conception of a special being which caused it and directed it. In later ages they had spirits in which there was everything: volatile liquids, gases, and theoretical conceptions, such as phlogiston. At the end of the last century, and at the beginning of our own, ideas being more rational, the notion of the "fluid" had been admitted, a mysterious and still vague enough category (but yet an already somewhat definite one) in which were ranged the unknown and ungraspable causes of caloric, luminous, electric, etc., phenomena. Gradually, the "fluid" has vanished, and we are left (or rather, we were a short time ago) at the notion of forces—a precise and mathematically graspable notion, but yet an essentially mysterious one. We see this conception gradually disappearing to leave finally only the elementary ideas of matter and motion—ideas, perhaps, which are not much clearer philosophically than the others, particularly that of matter taken per se, but which, at least, are necessary, since all the others supposed them.

Among those notions that study and time are reducing to other and simpler ones, that of electricity should be admitted; for it presents itself more and more as one of the peculiar cases of the general motion of matter. It will be to the eternal honor of Fresnel for having introduced into science and mathematically constituted the theory of undulations (already proposed before him, however), thus giving the first example of the notion of motion substituted for that of force. Since the principle of the conservation of energy has taken the eminent place in science that it now occupies, and we have seen a continual transformation of one series of phenomena into another, the mind is at once directed to the aspect of a new fact toward an explanation of this kind. Still, it is certain that these hypotheses are difficult of justification; for those motions that are at present named molecular, and that we cannot help presuming to be at the base of all actions, are per se ungraspable and can only be demonstrated by the coincidence of a large number of results. There is, however, another means of rendering them probable, and that is by employing analogy. If, by vibrations which are directly ascertainable, we can reproduce the effects of electricity, there will be good reason for admitting that the latter is nothing else than a system of vibration differing only, perhaps, in special qualities, such as dimensions, direction, rapidity, etc.

Such is the result that is attained by the very curious experiments that are due to Mr. Bjerknes. These constitute an ensemble of very striking results, which are perfectly concordant and exhibit very close analogies with electrical effects, as we shall presently see.

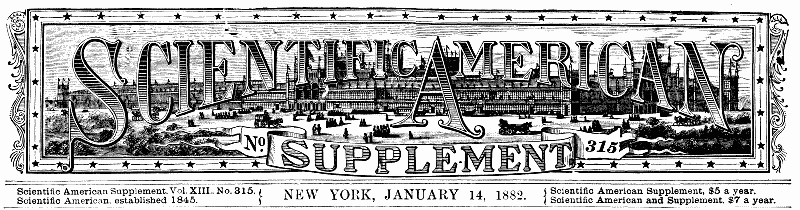

They are based on the presence of bodies set in vibration in a liquid. The vibrations produced by Mr. Bjerknes are of two kinds—pulsations and oscillations. The former of these are obtained by the aid of small drums with flexible ends, as shown to the left in Fig. 1. A small pump chamber or cylinder is, by means of a tube, put in communication with one of these closed drums in which the rapid motion of a piston alternately sucks in and expels the air. The two flexible ends are successively thrust outward and attracted toward the center. In an apparatus of this kind the two ends repulse and attract the liquid at the same time. Their motions are of the same phase; if it were desired that one should repulse while the other was attracting, it would be necessary to place two drums back to back, separated by a stiff partition, and put them in connection with two distinct pump chambers whose movements were so arranged that one should be forcing in while the other was exhausting. A system of this nature is shown to the right in Fig. 1.

The vibrations are obtained by the aid of small metal spheres fixed in tubular supports by movable levers to which are communicated the motions of compression and dilatation of the air in the pump chamber. They oscillate in a plane whose direction may be varied according to the arrangement of the sphere, as seen in the two apparatus of this kind shown in Fig. 1. Fig. 2 will give an idea of the general arrangement. The two pistons of the air-pumps are connected to cranks that may be fixed in such a way as to regulate the phases as may be desired, either in coincidence or opposition. The entire affair is put in motion by a wheel and cord permitting of rapid vibrations being obtained. The air is let into the apparatus by rubber tubing without interfering with their motions.

We may now enter into the details of the experiments:

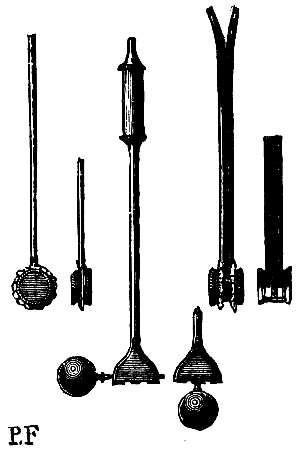

The first is represented in Fig. 2. In a basin of water there is placed a small frame carrying a drum fixed on an axle and capable of revolving. It also communicates with one of the air cylinders. The operator holds in his hand a second drum which communicates with the other cylinder. The pistons are adjusted in such a way that they shall move parallel with each other; then the ends of the drums inflate and collapse at the same time; the motions are of the same phase; but if the drums are brought near each other a very marked attraction occurs, the revolving drum follows the other. If the cranks are so adjusted that the pistons move in an opposite direction, the phases are discordant—there is a repulsion, and the movable drum moves away from the other. The effect, then, is analogous to that of two magnets, with about this difference, that here it is the like phases that attract and the different phases that repel each other, while in magnets like poles repel and unlike poles attract each other.

It is necessary to remark that it is indifferent which face of the drum is presented, since both possess the same phase. The drum behaves, then, like an insulated pole of a magnet, or, better, like a magnet having in its middle a succeeding point. In order to have two poles a double drum must be employed. The experiment then becomes more complicated; for it is necessary to have two pump chambers with opposite phases for this drum alone, and one or two others for the revolving drum. The effects, as we shall see, are more easily shown with the vibrating spheres.

This form has the advantage that the vibrating body exhibits the two phases at the same time; relatively to the liquid, one of its ends advances while the other recedes. Thus with a vibrating sphere presented to the movable drum, there may be obtained repulsion or attraction, according as the side which is approached is concordant or discordant with the end of the drum that it faces.

With the arrangement shown in Fig. 3 there may be performed an interesting series of experiments. The two spheres supported by the frame are set in simultaneous vibration, and the frame, moreover, is free to revolve about its axis. The effect is analogous to that which would be produced by two short magnets carried by the same revolving support; on presenting the vibrating sphere to the extremities the whole affair is attracted or repulsed, according to its phase and according to the point at which it is presented; on replacing the transverse support by a single sphere (as indicated in the figure by a dotted line) we obtain the analogue of a short magnet carried on a pivot like a small compass needle. This sphere follows the pole of a vibrating sphere which is presented to it, as the pole of a magnet would do, with this difference always, that in the magnet, like poles repel, while in oscillating bodies like phases attract.

In all the preceding experiments the bodies brought in presence were both in motion and the phenomena were analogous to those of permanent magnetism. We may also reproduce those which result from magnetism by induction. For this purpose we employ small balls of different materials suspended from floats, as shown in Fig. 4 (a, b, c). Let us, for example, take the body, b, which is a small metal sphere, and present to it either a drum which is caused to pulsate, on an oscillating sphere, and it will be attracted, thus representing the action of a magnet upon a bit of soft iron. A curious experiment may serve to indicate the transition between this new series and the preceding. If we present to each other two drums of opposite phases, but so arranged that one of them vibrates faster than the other, we shall find, on carefully bringing them together, that the repulsion which manifested itself at first is changing to attraction. On approaching each other the drum having the quicker motion finally has upon the other, the same action as if the latter were immovable; and the effect is analogous to that which takes place between a strong and weak magnet presented by their like poles.

By continuing these experiments we arrive at a very important point. Instead of the body, b (Fig. 4), let us take c. As the figure shows, this is a sphere lighter than water, kept in the liquid by a weight. If we present to it the vibrating body, it will be repelled, and we shall obtain the results known by the name of diamagnetism. This curious experiment renders evident the influence of media. As well known, Faraday attributed such effects to the action of the air; and he thought that magnetic motions always resulted from a difference between the attraction exerted by the magnet upon the body under experiment, and the attraction exerted by the air. If the body is more sensitive than the air, there is direct magnetism, but if it is less so, there is diamagnetism. Water between the bodies, in the Bjerknes experiments, plays the same role; it is this which, by its vibration, transmits the motions and determines the phases in the suspended body. If the body is heavier than water its motion is less than that of the liquid, and, consequently, relatively to the vibrating body, it is of like phase; and if it is lighter, the contrary takes place, and the phases are in discordance. These effects may be very well verified by the aid of the little apparatus shown in Fig. 5, and which carries two bars, one of them lighter and the other heavier than water. On presenting to them the vibrating body, one presents its extremity and takes an axial direction, while the other arranges itself crosswise and takes the equatorial direction. These experiments may be varied in different ways that it is scarcely necessary to dwell upon in this place, as they may be seen at the Electrical Exhibition.

Very curious effects are also obtained with the arrangement shown in Fig. 6. Between the two drums there is introduced a body sustained by a float such as represented at a, Fig. 4. Various results may, then, be obtained according to the combinations adopted. Let us suppose that the phases are alike, and that the interposed body is heavier than water; in this case it is repelled as far as the circumference of the drums, at which point it stops. If the phases are different, the influenced body behaves in the opposite manner and stops at the center. If the body is lighter than water the effects are naturally changed. Placed between two like phases, it is attracted within a certain radius and repelled when it is placed further off; if the phases are unlike, it is always repelled. We may easily assure ourselves that these effects are analogous to those which are produced on bodies placed between the poles of wide and powerful magnets. It is useless to repeat that the analogies are always inverse.

Mr. Bjerknes has carried the examination of these phenomena still further in studying experimentally the actions that occur in the depths of the liquid; and for this purpose he has made use of the arrangement shown in Fig. 7. By the side of the vibrating body there is placed a light body mounted on a very flexible spring. This assumes the motion of that portion of the fluid in which it is immersed, and, by the aid of a small pencil, its direction is inscribed upon a plate located above it. By placing this registering apparatus in different directions the entire liquid may be explored. We find by this means figures that are perfectly identical with magnetic phantoms. All the circumstances connected with these can be reproduced, the vibrating sphere giving the phantom of a magnet with its two poles. We may even exhibit the mutual action of two magnets. The figures show with remarkable distinctness—much more distinct, perhaps, than those that are obtained by true magnets.

However, it must not be thought that these so interesting facts are the result of groping in the dark and the outcome of some fortunate experiment; for they have, on the contrary, been foreseen and predetermined. Mr. Bjerknes is especially a mathematician, and it was a study, through calculation, of the vibratory motion of a body or system of bodies in a medium that led him to the results that he afterwards materialized.

After the production, by Mr. Lejeune, of his solutions, Mr. Bjerknes in 1865 entered upon a complete study of the subject, and recognized the fact that the result of such motions was the production of regular mechanical actions. He calculated the directions of these, and, along about 1875, perceived the possibility of reproducing the effects of permanent magnetism. More recently, in 1879, he saw that magnetism by derivation might likewise be explained by those hypotheses, and figured by actions of this kind. It was not till then that he performed the experiments, and submitted a body to the results of calculation.

The same process has led him to the conclusion that the action of currents might be represented in the same manner; only, instead of bodies in vibration, it would require bodies in alternating rotation. The effects are much more difficult to ascertain, since it is necessary to employ viscid liquids.

Meanwhile, the experiments have been performed. Up to the present time attractions and repulsions have not been shown, and I do not know whether Mr. Bjerknes has obtained them. But, by the process pointed out, the lines of action (electric phantoms, if I may so express myself) have been traced, and they are very curious. By supposing the current perpendicular to the plate, and in the presence of the pole of a magnet, the influences produced around it are very well seen, and the figures are very striking, especially in the case of two currents. Mr. Bjerknes does not appear as yet to have obtained from these experiments all that he expects from them. And yet, such as they are, they have already led him to important conclusions. Thus, calculation, confirmed by application, has led him to renounce the formula proposed by Ampère and to adopt that of Regnard as modified by Clausius. Is he right? This is what more prolonged experimentation will allow to be seen.

These researches, however, are beset with difficulties of a special nature, and the use of viscid liquids is a subject for discussion. Mr. Bjerknes desired to employ them for reproducing the effects that he had obtained from water, but he found that the lines of force were no longer the same, and that the phenomena were modified. It is necessary, then, to hold as much as possible to liquids that are perfect. The experimenter is at present endeavoring to use these liquids by employing cylinders having a fluted surface; but it is clear that this, too, is not without its difficulties.

This series of experiments offers a rare example of the verification of algebraic calculation by direct demonstration. In general, we may employ geometry, which gives a graphic representation of calculation and furnishes a valuable control. Sometimes we have practical application, which is a very important verification in some respects, but only approximate in others. But it is rare that we employ, as Mr. Bjerknes has done, a material, direct, and immediate translation, which, while it brings the results into singular prominence, permits of comparing them with known facts and of generalizing the views upon which they are based.

Hypotheses as to the nature of electricity being as yet only tolerably well established, we should neglect nothing that may contribute to give them a solid basis. Assuming that electricity is a vibratory motion (and probably there is no doubt about it), yet the fact is not so well established with regard to it as it is to that of light. Every proof that comes to support this idea is welcome, and especially so when it is not derived from a kind of accident, but is furnished by a calculated and mathematical combination. Viewed from this double standpoint, the experiments of Mr. Bjerknes are very remarkable, and, I may add, they are very curious to behold, and I recommend all visitors to the Exhibition to examine them.—Frank Geraldy, in La Lumiere Electrique.

I shall experience one difficulty in addressing you this evening, which is, that although I do not wish to take up your time with purely elementary matter, I wish to make the subject clear to those who may not be familiar with its earlier struggles.

If we begin at the beginning we have to go back to the time when Faraday made the discovery that light could be produced by the separation of two carbon rods conducting a current of considerable tension. That is the historical point when electric lighting first loomed up as a giant possibility of the near future. This occurred about the year 1846. In some experiments he found that although the circuit could not be interrupted by any considerable interval when metallic terminals were used without breaking the current, when carbon was substituted the interval could be largely increased, and a light of dazzling brilliancy appeared between the points.

This remarkable effect appears to be produced by the rarefaction of the air, due to the great heat evolved by the combustion of the carbon, and also to the passage of incandescent particles of carbon from pole to pole, thus reducing the resistance, otherwise too great for the current tension.

That was the beginning of electric lighting; and perhaps it will be well to bridge the long and comparatively uninteresting interval which elapsed between this discovery and the equally important one which alone gave it commercial value—I refer to the production of suitable currents by mechanical means. That is to say, the substitution of energy obtained from coal in the form of steam power reduced the cost to a fraction of what it necessarily was when the galvanic elements were used. Here is the point; the cost of zinc today is something over fifty times that of coal, while its energy as a vitalizing agent is only about five times greater, leaving a very large margin in favor of the "black diamonds." This is not the only advantage, for the resulting impulse in the case of mechanical production is much more uniform in action, and therefore better suited to the end in view, while the amount of adjustment and attention required is beyond comparison in favor of the latter means.

The machines adopted were of the magneto variety, and many ingenious machines of this class were operated with more or less success, being, however, quickly abandoned upon the introduction of the dynamo-machine, which gave currents of much greater electromotive force from the same amount of material, the advantage being chiefly due to the large increase of magnetic intensity in the field magnets. At this period lights of enormous power were produced with ease and by the use of costly lamps. With complicated mechanism a new era in artificial illumination seemed close at hand, but a grave difficulty stood in the way—namely, the proper distribution or subdivision of the light. It was quickly found that the electric difficulty of subdividing the light, added to the great cost of the lamps then made, was an apparently insurmountable obstacle to its general adoption, and the electric light was gradually taking its place as a brilliant scientific toy, when the world was startled by the introduction of the Jablochkoff candle, which may fairly claim to have given a greater impetus to the new light than any previous invention, a stimulus without which it is even probable that electric lighting might have slumbered for another decade.

The Jablochkoff candle embodies a very beautiful philosophical principle, and though its promises have not been fulfilled in general practice, we must not forget that we owe it much for arousing scientific men from a dangerous lethargy.

Up to this time the light had always been produced by approximation of carbon rods with their axes in the same plane; but the Jablochkoff candle consisted of like rods arranged parallel to each other and about one-eighth of an inch apart, the intervening space being filled with plaster of Paris, and the interval at the top bridged by a conducting medium. The object of the plaster, which is a fairly good insulating material at ordinary temperatures, is to prevent the passage of the current except at the top, where the conducting material just referred to assisted the formation of the arc at that point, and the resulting intense heat maintained the plaster in a moderately conducting state until the whole carbon was consumed. Here, then, was literally an electric "candle," which could be operated without the costly and unsteady lamps, and fortunately its birthplace was Paris—then the center of philosophical research; from that period the future of electric lighting was assured.

When we reflect that owing to the greater disruptive energy of the positive terminal, the carbon so connected to an ordinary dynamo machine is consumed very much faster than the negative—sometimes in the ratio of 3 to 1—it will be clear that some other means of consuming the Jablochkoff candle had to be used, since the arc would cease to exist in a very short time by reason of the unequal consumption of the carbons, and the subsequent increase of the intervening space beyond the limit of the current tension.

This difficulty M. Gramme overcame with characteristic ingenuity by adding to the ordinary system a "distributer" capable of delivering plus and minus currents alternately, thus equalizing the consumption, besides being able to supply a large number of candles on the multiple circuit system, each circuit supporting four or five lamps. Thus it will be seen that a result was attained which at least gave such men as Siemens, Gramme, and their peers, if such there be, confidence in the future and a courage which quickly placed the new science safely beyond the limits of the laboratory. I will not occupy your time by stating the apparent reasons why the Jablochkoff candle has not fully sustained its brilliant promise—it will, perhaps, be sufficient to state that it is now superseded practically, though it must always occupy an honorable place in scientific annals.

Let us now for a few moments consider what the electric light really accomplished at about this period, I mean from an economical standpoint. It appears from some data furnished by an engineer commissioned by the French Government that the machines were then capable of maintaining a light equal to from 220 to 450 candles, measured by comparison with the Carcel burner, per horse power absorbed—a very good showing considering the youth of the discovery, but presenting rather a gloomy aspect when we consider that according to Joule's mechanical equivalent of heat, which is 772 foot pounds, or the power required to raise one pound of water one degree—and for lack of anything better, we are obliged to accept that at this moment—the whole force contained in one pound of coal would maintain a light equal to 13,000 candles for one hour! That is the ultimate force, and what we are now able to accomplish is but a small fraction of this amount.

Unfortunately we are but common mortals, and cannot, like Mr. Keely, lightly throw off the trammels of natural law; we must, therefore, endeavor to close this gap by patient study and experiment.

The limited time at my disposal, and a keen consideration for your feelings, will not permit me to follow the long series of struggles between mind and matter immediately following Jablochkoff's brilliant invention; suffice it to say, that the few years just passed have yielded beyond comparison the most marvelous results in the scientific history of the world, and it will be superfluous to remind you that a great part of this has undoubtedly been due to the researches made in an effort to reduce electric lighting to a commercial basis. To say that this has been fully accomplished is but to repeat a well known fact; and in proof of this I quote a high scientific authority by stating that a result so high as 4,000 candles evolved for 40,000 foot-pounds absorbed has recently been obtained—an efficiency six or seven times greater than the record of six years ago. In accepting this statement we must not lose sight of the extreme probability that such effects were evolved under conditions rarely if ever found in common practice. Of course, I now refer to the arc system. The volume of light so generated is incomparably greater than by any other known method, though in subdivision the limit is sooner reached.

Mr. Hawkesworth—Let me ask you a question, please. Supposing that it required a one-horse power to produce an arc light of, say, 2,000 candles, would it be possible to produce ten arc lights of 200 candles each?

Mr. Daft—No, sir; I will tell you why. It would, if no other element than the simple resistance of the arcs opposed the passage of a current; then a machine that would produce an inch arc in one light, if placed on a circuit of sixteen lamps would give to each an arc one-sixteenth of an inch long naturally; but another difficulty here presents itself in the shape of a resisting impulse of considerable electromotive force in the opposite direction, apparently caused by the intense polarity of the two terminals. The resistance of the arc itself varies much according to the volume of current used being usually small with a large quantity of current, and greater with a current of tension; but this opposing element is always found, and appears to be the only real obstacle in the way of infinite subdivision.

Almost every objection which human ingenuity could suggest has been urged against lighting by electricity, but fortunately electricians have been able in most cases either to meet the difficulty or prove it groundless.

In this connection I am led to speak of the common idea that electric light is injurious to the eyes, first, because of its unsteady character, and secondly, by reason of the great excess of the more refrangible rays. Both objections undoubtedly hold good where the alleged causes exist; but we can now show you a light which is certainly as steady as the ordinary gaslight—indeed more steady in an apartment where even feeble currents of air circulate; and I am sure you will readily acknowledge that the latter objection is disposed of when I assure you that our light presents the only example with which I am acquainted of an exact artificial reproduction of the solar light, as shown by decomposition. The two spectra, placed side by side, show in the most conclusive manner the identity in composition of our light with that of the sun.

The remarkable coolness of the electric light, as compared with its volume by gas, is also due in a great measure to the conspicuous absence of that large excess of less refrangible, or heat-radiating principle, which distinguishes almost equally all other modes of artificial illumination. After the foregoing statement it may seem a paradox to claim that the electric arc develops the greatest heat with which we have yet had to deal, but this is so; and the heat has an intensity quite beyond the reach of accurate measurement by any instrument now known—it has been variously estimated anywhere between 5,000° and 50,000° F. It is sufficient for our present purpose to know that the most refractory substances quickly disappear when brought under its influence—even the imperial diamond must succumb in a short time. In order to reconcile this fact with its coolness as an illuminating agent, we have to take into consideration the extreme smallness of the point from which the light radiates in the electric arc. A light having the power of many thousand candles will expose but a fraction of the surface for heat radiation which is shown by one gas-jet, and, as I have endeavored to explain, these rays contain very much less of the heating principle than those from gas or other artificial light.

The purity of electric light has another important aspect, which can scarcely be overestimated—namely, the facility with which all the most delicate shades of color can be distinguished. I understand from persons better skilled than myself in such matters that this can be done almost as readily by electric as by day light, and I have little doubt that the slight difference in this respect will entirely disappear when people become somewhat more familiar with the different conditions—the effect of such shades viewed by electric light being more like that with comparatively feeble direct sunlight than the subdued daylight usually prevailing in stores and warehouses.

Again, it has frequently been urged that persons working by electric light have thus induced inflammation of the eyes. No doubt this is so with light containing the highly refrangible rays in excess; but it is difficult to see how such an effect can occur with light composed as is the light with which the eyes are constructed to operate in perfect harmony.

As you are aware, there are other methods of obtaining light by electric energy, and in order to make a fair comparison of one which has lately attracted a great deal of attention and capital, I will relate to you the result of observations made during a recent visit to the office of an eminent electrician. The light was that known as incandescent—a filament of carbon raised to a light-emitting heat in vacuo. The exclusion of the air is necessary to prevent the otherwise rapid destruction of the carbon by combination with oxygen. At the time of my visit there were 62 lamps in circuit. According to their statement each lamp was of 16-candle power—I accept their statement as correct; this will give us an aggregate of 992 candles. The generator was vitalized by an engine rated by the attendants in charge at 6-horse power. I found that it was a 5×7 cylinder, working with very little expansion 430 revolutions per minute, with 90 pounds of live steam, in a boiler not 15 feet from the engine. I have every reason to believe that the steam was delivered at the cylinder with an almost inappreciable loss on 90 pounds. Under those conditions I think it is perfectly fair to assume (you have the data, so that you can calculate it afterwards) that 750,000 foot pounds were consumed in producing those 60 lights, aggregating 992 candles. In the kind of engine they had, 750,000 foot pounds requires a consumption of about 100 pounds of coal per hour. It was an ordinary high speed engine. That 750,000 foot pounds, I assume, required 100 pounds of coal. That is the only weak point in my data; I do not know that to be true; but I never saw an engine of that form yet capable of delivering 1-horse power with less consumption than four to five pounds of coal per horse power per hour. I want to be as fair as I can in the matter. I wish to compare this, as they have taken particular pains to compare it, with gas, at the present cost of gas.

The hundred pounds of coal will produce 400 feet of gas; 400 feet of gas will evolve the effect of 1,500 candles. So you see the position we are in. In consuming that coal directly by destructive distillation you can produce 1,500 candles light; by converting it into power, and then again into light by incandescence, you produce 992! Expressing this in other words, we may say that in producing the light from coal by the incandescent system you lose one-third of the power as compared with gas, by actually converting the coal into gas, and delivering it in the ordinary manner. Those are facts. It has been suggested to me that I am too liberal in my estimate of coal consumed—that those engines consume more than four or five pounds per horse power per hour; but I prefer to give them the benefit of the doubt.

Mr. Rothschild—If I understood you correctly, this electric light costs more than gas?

Mr. Daft—Must do by this system. You cannot do better, so far as our philosophy goes. But this whole system of illumination, as now practiced is a financial fallacy.

Mr. Rothschild—That is what Professor Sawyer says.

Mr. Daft—The same amount of energy converted into light by our arc system will produce 30,000 candles. We are perfectly willing to demonstrate that at any time. I am free to admit that the minute subdivision obtained by the Edisonian, Swan, or Fox system—they do not differ materially—is a great desideratum; but this cannot bridge the financial gulf.

Mr. Lendrum—Now please state what we have accomplished.

Mr. Daft—Certainly; and in so doing I prefer to give our results as actually occurring in everyday work; and in this connection let me remind you that in no branch of physics are the purely experimental effects so well calculated to deceive, if not fairly conditioned. As we have seen, it is claimed on excellent authority that the equivalent of 4,000 candles appeared in an arc by expending 40,000 foot pounds of energy at the generator, but with everyday conditions it is at present idle to expect such efficiency. Commercially we can give by our own system 3,000 candles for 40,000 foot pounds absorbed; this may be done for an indefinite length of time and leave nothing to be desired on the score of steadiness. Unfortunately there is no unit of photometric measurement generally recognized in this country, each electrician having so far adopted one to suit his own convenience; but in making the foregoing statement I wish it to be understood that our efficiency would appear still greater if measured by some of the methods now employed. For our own satisfaction we have endeavored to be at least approximately accurate, at the same time wishing to avoid the affectation of extreme precision, such, for example, as adding twenty or thirty candles to measurements of so many thousands, and we are satisfied that the most critical expert tests will prove our claim to be within the mark. The limit of subdivision is only reached when the difficulty of further increasing the electromotive force of the machines, involving great care in insulation and a host of other troubles arising, so to speak, at very high pressure, is balanced by the objections to working in multiple arc; this appears to occur now at something below 40 lights, but will in all probability be greatly extended within a short time. The machines are so constructed that the local currents, usually productive of dangerous heating, are turned to useful account, so that the point where radiation exceeds production is soon reached, and provided the machines are not speeded beyond the proper limit, they may be run continuously without the slightest indication of lost vitality. I need scarcely remind you that this is a most important feature, and by no means a common one.

The lamps used in our system I believe to be the simplest known form of regulator; indeed it seems scarcely possible that anything less complicated could perform the necessary work; as a matter of fact we may confidently assert that it cannot be made less liable to derangement. It has frequently been placed on circuit by persons totally inexperienced in such matters, and still has yielded results which we are quite willing to quote at any time.

I will not now trespass on your patience further than will enable me to state that experiments now in hand indicate conclusively that domestic electric lighting of the immediate future will be accomplished in a manner more beautiful and wondrous than was ever shadowed in an Arabian Night's dream. I hesitate somewhat to make these vague allusions, since so many wild promises, for which I am not responsible, remain unfulfilled, but the time is surely near at hand when a single touch will illuminate our homes with a light which will combine all the elements of beauty, steadiness, softness, and absolute safety, to a degree as yet undreamed of. I do not ask you to accept this without question, but only to remember that within the last decade wires have been taught to convey not only articulate sounds, but the individual voices you know amidst a thousand, and even light and heat have each been made the medium of communicating our thoughts to distant places!

Not the least remarkable phenomenon in this connection is the intellectual condition of the people who have welcomed these marvelous achievements and allowed them to enter into their everyday life, thus removing the greatest barriers of the past and paving the way for that philosophical millennium inevitably awaiting those who may be fortunate enough to survive the next decade.

A recent address before the New York Electric Light Association.

The travel over the elevated steam street railways of New York city for month of October, 1881, was the heaviest yet recorded, aggregating 7,121,961 passengers, as against 5,881,474, for the corresponding month of 1880, an increase of 1,240,487, representing just about the entire population of the city.

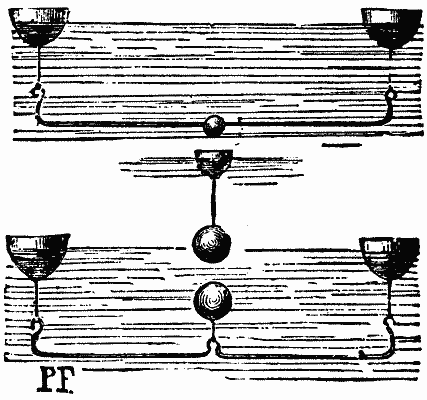

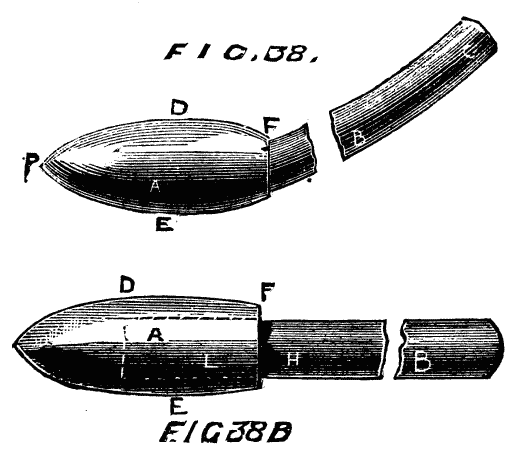

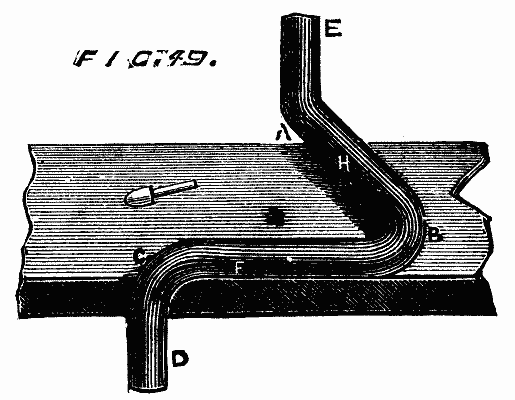

We illustrate a very curious and interesting form of electric regulator which is exhibited in the Paris Exhibition of Electricity by Mr. Killingworth Hedges, whose name will be known to our readers as the author of a little book on the electric light. Mr. Hedges' lamp belongs to the same category of electric regulators as the lamp of M. Rapieff, and to one form of M. Reynier's lamp, that is to say, the position of the ends of the carbons, and therefore of the arc, is determined not by clockwork or similar controlling mechanism, but by the locus of the geometrical intersection of the axes of the carbon rods, the positions of which axes being determined by simple mechanical means.

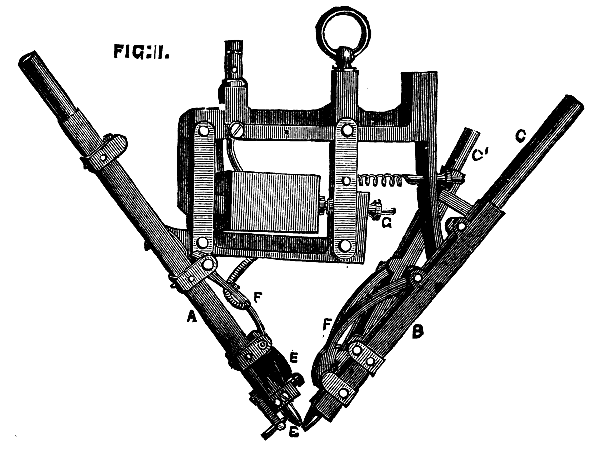

Referring to Fig. 1, A and B are two troughs rectangular in cross section attached to the supports in such positions that their axes are inclined to one another so as to form the letter V, as shown in the figure. Within these troughs slide freely the two carbon pencils, which are of circular cross section, meeting, when no current is passing, at the lower point, E. The carbon-holder, B, to the right of the figure, is rigidly attached to the framing of the lamp, but the trough, A, which carries the negative carbon, is attached to the framing by a pivot shown in the figure, and on this pivot the carbon holder can rock, its motion being controlled by the position of the armature of an electro-magnet, M, the coils of which are included in the circuit of the apparatus. By this means, the moment the current is established through the lamp, the armature is attracted, and the points of the two carbons are separated, thus forming the arc. The positive carbon, B, is held from sliding and dropping through the trough by the gentle pressure against it of the smaller carbon rod, C¹, which also slides in a trough or tube fixed in such a position that the point of contact between the two rods is sufficiently near the arc for the smaller rod to be slowly consumed as the other is burnt away; the latter in that way is permitted to slide gradually down the trough as long as the lamp is in action. The negative carbon-holder, A, is provided with a little adjustable platinum stop, E, which by pressing against the side of the conical end of the negative carbon, holds the latter in its place and prevents it sliding down the trough except under the influence of the slow combustion of the cone during the process of producing the arc. The position of the stop with respect to the conical end is determined by a small adjusting screw shown in the figure. This arrangement of stop is identical in principle with that adopted by Messrs. Siemens Brothers in their "abutment pole" lamp, and is found to work very well in practice on the negative electrodes, but is inapplicable on the positive carbons on account of the higher temperature of the latter, which is liable to destroy the metallic stop by fusion, and it is for this reason that the positive carbon in Mr. Hedges' lamp is controlled by the method we have already described. For alternating currents, however, the abutment stop may be used on both electrodes.

In order to maintain a good electrical contact between the fixed conducting portions of the lamp and the sliding carbons, Mr. Hedges fits to each carbon-holder a little contact piece, F F, hinged to its respective trough at its upper end, and carrying at its lower or free end a somewhat heavy little block of brass grooved out to fit the cylindrical side of the carbon, against which it presses with an even pressure. This arrangement offers another advantage, namely, that the length of that portion of the carbon rods which is conveying the current is always the same notwithstanding the shortening of their total length by combustion; the resistance of the carbon electrodes is, therefore, maintained constant, and, for the reason that the contact piece presses against the rods very near their lower ends, that resistance is reduced to a minimum. In this way very long carbons, such, for instance, as will burn for ten or sixteen hours, can be used without introducing any increase of resistance into the circuit. The length of the arc can be determined by the adjustment of the screw, G, by which the amount of movement of the armature is limited.

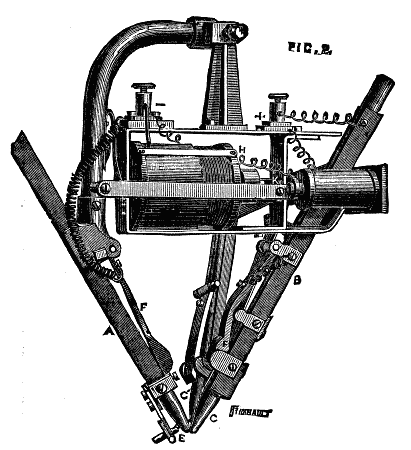

Fig. 2 represents a modified form of Mr. Hedges' lamp designed for installation when it is desirable to burn a number of lamps in series. In this arrangement the carbons are separated by the attractive influence of a solenoid upon an iron plunger, to which is attached (by a non-magnetic connection) the armature of an electro-magnet, the coils (which are of fine wire) forming a shunt circuit between the two terminals of the lamp, and so disposed with respect to the armature as to influence it in an opposite direction to that of the solenoid. When the circuit of the lamp is completed with the electric generator the carbons are drawn apart by the action of the solenoid on the plunger, and the distance to which they are separated is determined by the difference of attractive force exercised upon the armature by the solenoid and the magnet; but as the latter forms a short circuit to that of the arc, it follows that should the resistance of the arc circuit increase either through the arc becoming too long or through imperfection in the carbons or contacts, a greater percentage of current will flow through the magnet coils, and the arc will be shortened, thereby reducing its resistance and regulating it to the strength of the current. In other words, the distance between the carbons, that is to say, the length of the arc, is determined by the position of the armature of the electro-magnet between its magnets and the solenoid, which position is in its turn determined by the difference between the strength of current passing through the coil of the solenoid and that of the magnet.

Mr. Killingworth Hedges exhibits also a third form of his lamp, in most respects similar to the lamp figured in Fig. 1, but in which the ends of the two carbons rest against the side of a small cylinder of fireclay or other refractory material, which is mounted on a horizontal axis and can be rotated thereon by a worm and worm-wheel actuated by an endless cord passing over a grooved pulley. In the lamp one of the carbon-holders is rigidly fixed to the framing of the apparatus, and the other is mounted on a point so as to enable the length of the arc playing over the clay cylinder to be regulated by the action of an electro-magnet attracting an armature in opposition to the tension of an adjustable spring.

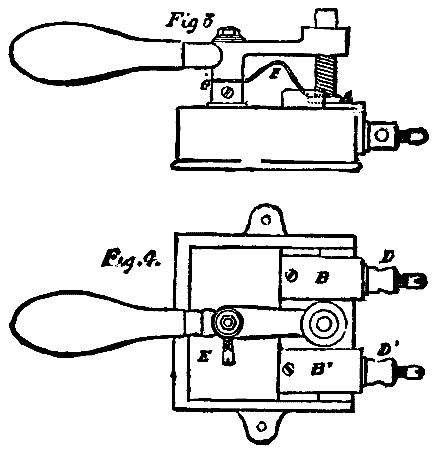

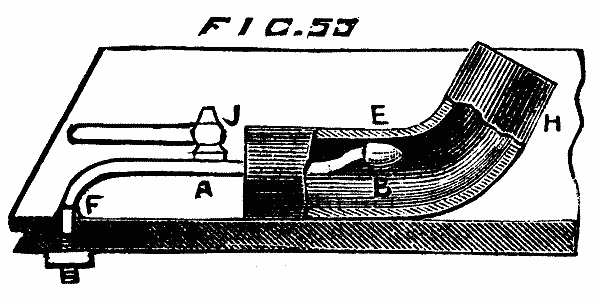

In the same exhibit will be found specimens of Mr. Hedges' two-way switches, which have been designed to reduce the tendency to sparking and consequent destruction which so often accompanies the action of switches of the ordinary form. The essential characteristic of this switch, which we illustrate in elevation in Fig. 3 and in plan in Fig. 4, lies first in the circular form of contact-piece shown in Fig. 4, and next in the fact that the space between the two fixed contact-pieces is filled up with a block composed of compressed asbestos, the surface of which is flush with the upper surfaces of the two contact-pieces. The circular contact-piece attached to the switch lever can be turned round so as to present a fresh surface when that which has been in use shows indications of being worn, and a good firm contact with the fixed contact-pieces is insured by the presence of a spiral spring shown in the upper figure, and which, owing to an error in engraving, appears more like a screw than a spring. In order to prevent bad connection through dust or other impurities collecting within the joint, the electrical connection between the fulcrum of the switch lever and the circular contact-piece is made through the bent spring shown edgeways in Fig. 3.—Engineering.

Lartigue's Switch Controller.—The object of this apparatus is to warn the switch tender in case the switch does not entirely respond to the movement of the maneuvering lever.

The apparatus, which is represented in the accompanying Figs. 1, 2, 3, and 4, consists of the following parts:

(1.) A mercurial commutator, O, which is fixed on a lever, B, connected with a piece, A, which is applied against the external surface of the web of the main rails, opposite the extremity of the switch plates;

(2.) A bar, C, which traverses the web of the rail and projects on the opposite side, and which carries a nut, D, against which the switch plate abuts;

(3.) An electrical alarm and a pile, located near the switch lever. As long as one of the two plates of the switch is applied against the rail, one of the two commutators is inclined and no current passes. A space of one millimeter is sufficient to bring the commutator to a horizontal position and to cause the electric alarm to ring continuously. If the apparatus gets out of order, it is known at once; for if the alarm does not work during the maneuver of the switch, the tender will be warned that the electric communications are interrupted, and that he must consequently at once make known the position of his switch until the necessary repairs have been made.

Pedals for Transmitting Signals to Crossings.—On railways having a double track and doing a large amount of business it becomes very necessary to announce to the flagmen at railway crossings the approach of trains, so as to give them time to stop all crossing of the tracks. On railway lines provided with electro-semaphores there may be used for this purpose those small apparatus that have been styled semaphore repeaters.

Mr. Lartigue has invented two automatic apparatus, by means of which the train itself signals its approach.

1. The first of these, which is generally placed at about 6,000 feet from the point to be covered, consists (Figs. 5, 6, 7, and 8) of a very light pedal fixed to the inside of the rail, and acting upon a mercurial commutator. A spring, R, carried upon the arm, a, of a lever, A, projects slightly above the level of the rail, while the other arm, b, carries a commutator.

The spring, R, on being depressed tilts the box containing the mercury, closes the circuit, and causes an alarm, S, located at the crossing, to immediately ring. In this alarm (Fig. 8) a piece, P, is disconnected by the passage of the current into the electro-magnet, E, which attracts the armature, a, and, a permanent current being set up, the apparatus operates like an ordinary alarm, until the piece, P, is placed by hand in its first position again.

2. The second apparatus, exhibited by the Railway Company of the North, and also the invention of Mr. Lartigue, bears the name of the "Bellows Pedal." It consists (Figs. 9 and 10) of a pedal, properly so called, P, placed along the rail, one of its extremities forming a lever and the other being provided with a counterpoise, C. When a train passes over the pedal, the arm, B, fixed to its axle, on falling closes the circuit of an ordinary electrical alarm, and at the same time the bellows, S, becomes rapidly filled with air, and, after the passage of the train, is emptied again very slowly under the action of the counterpoise. The contact is thus kept up for some few minutes. This apparatus works very satisfactorily, but is cumbersome and relatively high-priced.

The Brunot Controller as a Controller of the Passage of Trains.—The Brunot Controller, which has been employed for several years on the Railway of the North, is designed to control the regularity of the running of trains, and to make automatically a contradictory verification of the figures on the slips carried by the conductors. In Fig. 11 we give a longitudinal section of the apparatus. It consists of a wooden case containing a clockwork movement, H, upon the axle of which is mounted a cardboard disk, C, divided into hours and minutes, and regulated like a watch, that is to say, making one complete revolution in twelve hours. The metallic pencil, c, which is capable of displacing itself on the cardboard in a horizontal direction opposite a groove on the other side of the disk, traces, when pressure is brought to bear on it, a spiral curve. The transverse travel of the pencil is effected in ninety-six hours. The displacement of the pencil is brought about by means of a cam. Under the influence of the jarring of the train in motion, a weight, P, suspended from a flexible strip, l, strikes against the pencil, c, which traces a series of points. During stoppages there is, of course, an interruption in the tracing of the curve.

Up to this point no electricity is involved—the apparatus is simply a controller of regularity. Mr. Brunot has conceived the idea of utilizing his apparatus for controlling the passage of trains at certain determined points on the line; for example, at the top of heavy grades. For this purpose it has only been necessary to add to the apparatus that we have just described an electro-magnet, E, connected electrically with a fixed contact located on the line. When the current passes, that is to say, at the moment the circuit is closed by the passage of a train, the armature, A, is attracted, and the pencil marks a point on the cardboard disk. This modification of the apparatus has not as yet been practically applied.

Electrical Corresponding Apparatus.—The object of these apparatus is to quickly transmit to a distance a certain number of phrases that have been prepared in advance. The Company of the North employs two kinds of correspondence apparatus—the Guggemos and the annunciator apparatus.

1. The Guggemos Apparatus.—This apparatus serves at once as a manipulator and receiver, and consists of an inner movement surmounted by a dial, over the face of which moves an index hand. Around the circumference of the dial there is arranged a series of circular cases, C, containing the messages to be received, and similar triangular cases, containing the messages to be forwarded, radiating from the center of the dial. Between each of these there is a button, b.

Fig. 13 represents the interior of an apparatus for twenty messages. It consists of a key-board, M, an electro-magnet, B, a clock-work movement, Q, an escapement, s, and an interrupter, F G.

When one of the buttons, b, is pressed, one of the levers of the key-board arrangement touches the disk, M, which is insulated from the other portions of the key-board, and the current then passes from the terminal C to M, and there bifurcating, one portion of it goes to the bobbins of the apparatus and thence to the earth, while the other goes to actuate the correspondence apparatus. The index-hands of the two apparatus thereupon begin their movement simultaneously, and only stop when the pressure is removed from the button and the current is consequently interrupted. H is a ratchet-wheel, which, like the key-board, is insulated from the rest of the apparatus. The button, K, located over each of the dials, serves to bring the index-needles back to their position under the cross shown in Fig. 12. The key, X, serves for winding up the clock-work movement.

The Annunciator Apparatus.—This apparatus, which performs the same role as the one just described, is simply an ingenious modification of the annunciator used in hotels, etc.